Often it is needed to chart in real time the values coming from the serial port (RS-232). In Arduino environment it is a common need. If you have some values, only one possibility is offered by the Arduino IDE: to use the serial monitor. But on the serial monitor, the values are textual and also they are difficult to read during the elaborations. You can use Processing, but Processing is complicated when you like to show many graphics or when you like to see graphic and text values, when you like to customize the graphic. You must program in Java.

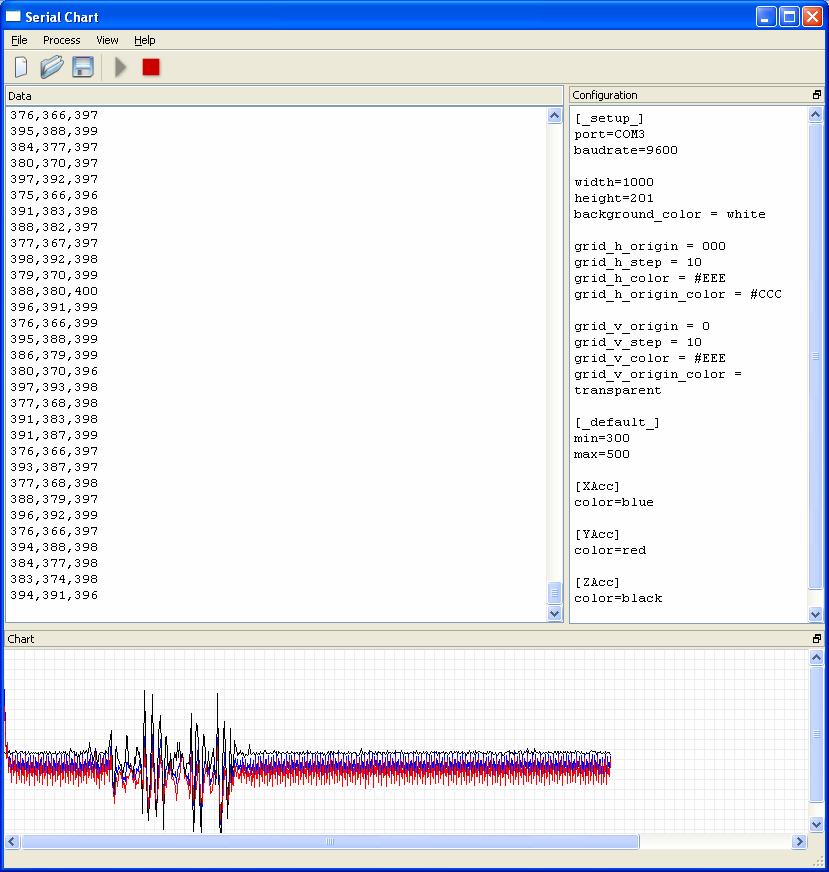

I discovered a simple tool made with QT graphic libraries, that needs only a light parametrization for plotting in an easy way the serial values. The sw is SERIALCHART.

Easily it is possible to customize the graphic and modify the colors without become crazy. The sw is explained here. You have to use also an easy configuration file explained here.

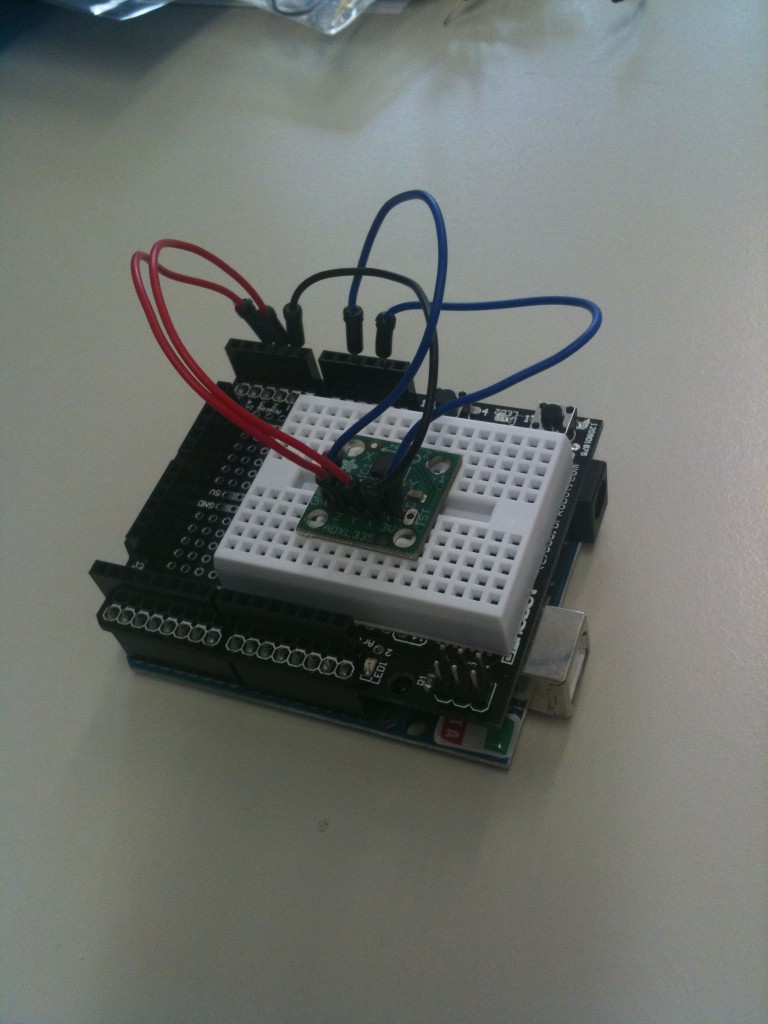

I made a test to see in a graphic the values read by a 3-axis accelerometer wired to an Arduino.

The code to read 3 axis from Arduino is very easy:

// read x,y,z accelerometer values // set input variables int analogInput0 = 0; int analogInput1 = 1; int analogInput2 = 2; // store input variables int value0 = 0; int value1 = 0; int value2 = 0; void setup(){ // set input pins pinMode(analogInput0, INPUT); pinMode(analogInput1, INPUT); pinMode(analogInput2, INPUT); // begin serial port communication Serial.begin(9600); } void loop(){ // read accelerometer values value0 = analogRead(analogInput0); value1 = analogRead(analogInput1); value2 = analogRead(analogInput2); // print values in the serial port, separated by comma Serial.print(value0); Serial.print(","); Serial.print(value1); Serial.print(","); Serial.println(value2); // wait and loop again delay(100); }

The output produced by SerialChart is shown in the picture below, where I inserted also the parametrization made.