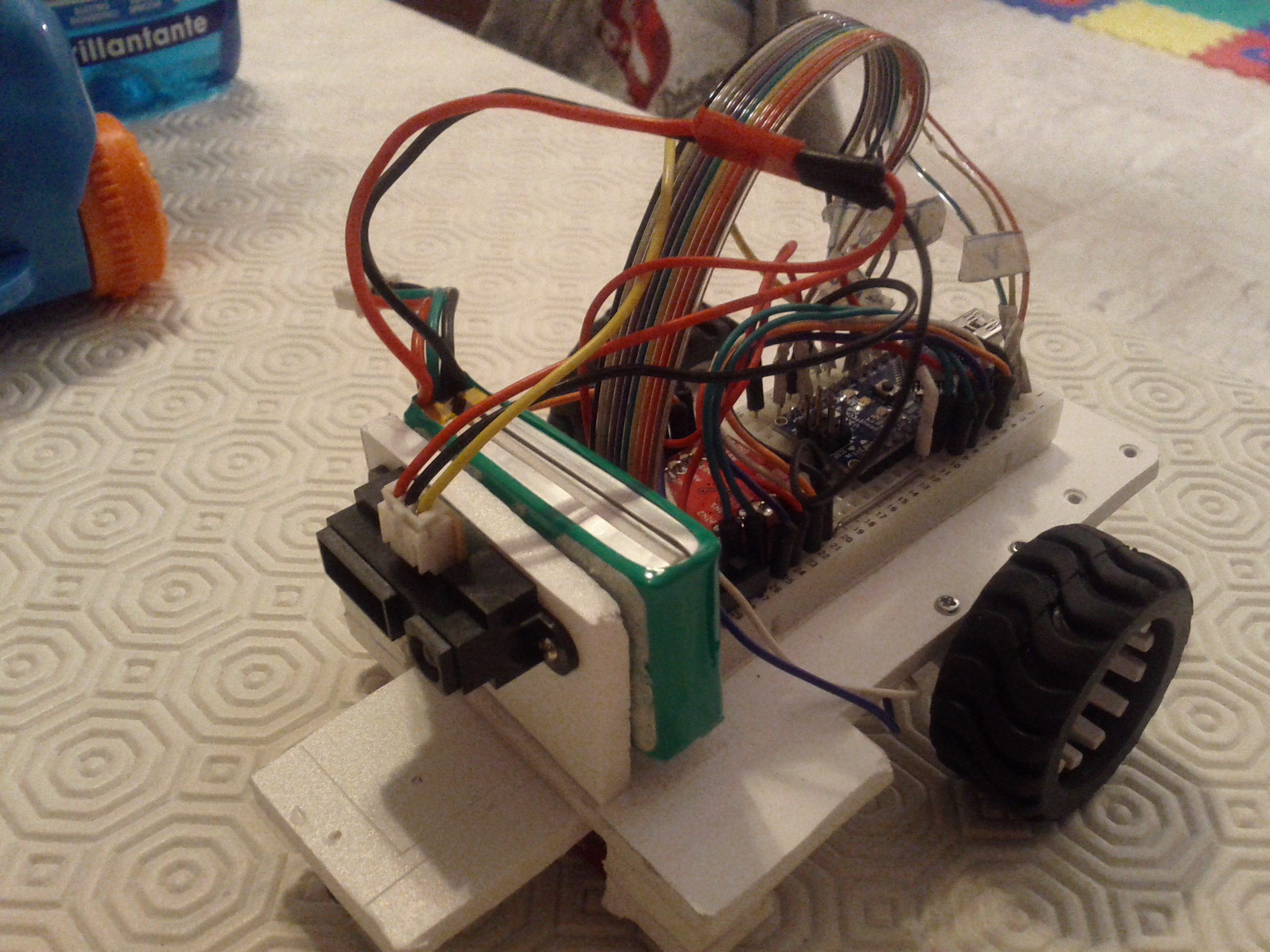

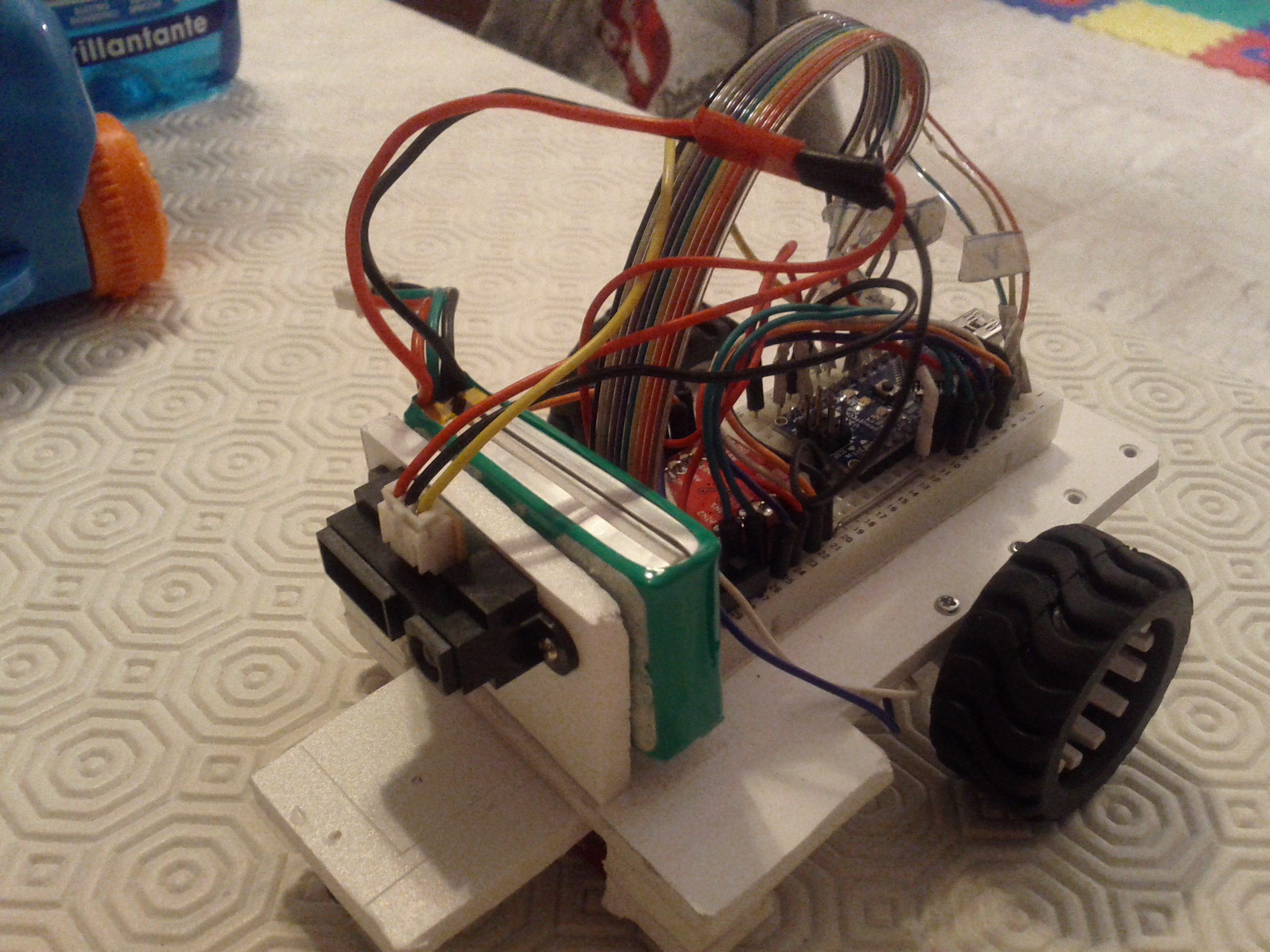

Microbo(t) – Advanced line follower

Although it is one of the classics of robotics for beginners, the line follower robot, made at high level, is quite complex. On Youtube you can see line follower running at 3 m /…

Seamless Theme Primrose, made by Altervista

Create a website and earn with Altervista - Disclaimer - Report Abuse - Privacy Policy - Customize advertising tracking