Linea is my first line follower based on Arduino.

A line follower is a robot for beginners. In fact it is very simple to build a line follower and only few components are required :

– a robot chassis

– IR sensors for line tracking (black or white line)

– two motors (servos or gear motors)

– an Arduino to drive the motors and to implement control logic

– Batteries, jumpers, screws and other hardware

If you use gear motors it is important to use also a motors driver, because Arduino can’t feed the motors with the high current required.

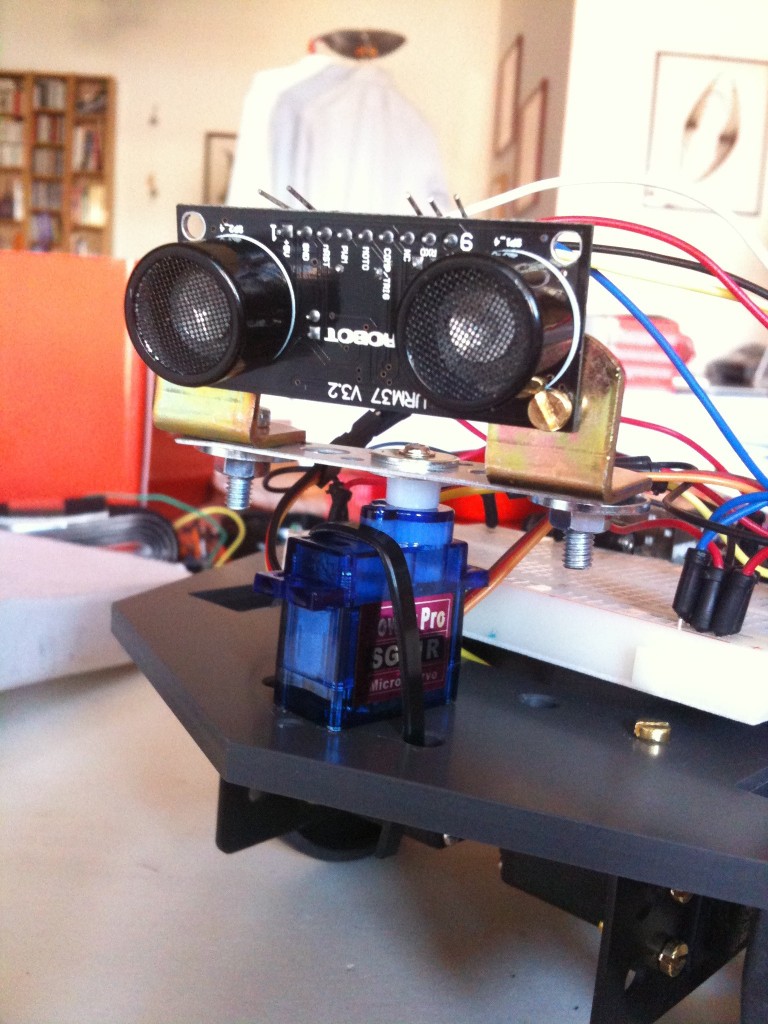

IR SENSORS

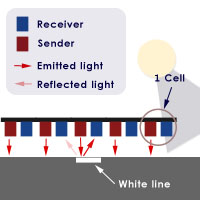

The sensors used in line follower robot are Infrared sensors and they are made with 2 different components:

– a light emitter

– a light receiver

When the emitter emits light, the light is reflected by the floor. If the line is white and the sensor is above the line, the white line reflect all the light, so it permits to understand that the sensor is effectively above the line. Instead if the sensor is over the black surface, the sensor doesn’t reflect the light, so we can understand that the sensor isn’t above the line.

If we have many IR sensors, knowing which sensor is above the line, lets to understand if the robot is going out from the middle of the line, at the right or the left side. In the picture above are shown 5 sensors, but is not unusual to use 8 or 10 sensors. The minimum required is 3 sensor (left, straight, right).

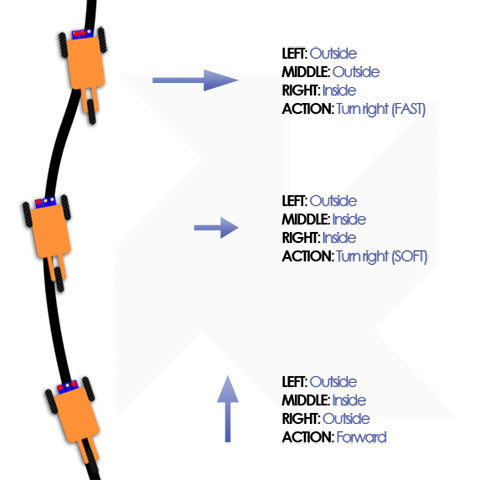

The CONTROL

The robot, mostly if the line is curved, will go out of the path. It is important to teach to the robot how to maintain above the line. Usually, it is possible to do this with a motion control and the PID (Proportional-derivative-integral) control is the most famous. This control will try to compensate the error, i.e. the misalignment from the line. You can find some details about PID in wikipedia.

This picture shows the criteria used for the control:

The combined readings from the sensors are used to understand if the correction done by the control have to be hard or soft.

Linea – The line follower robot

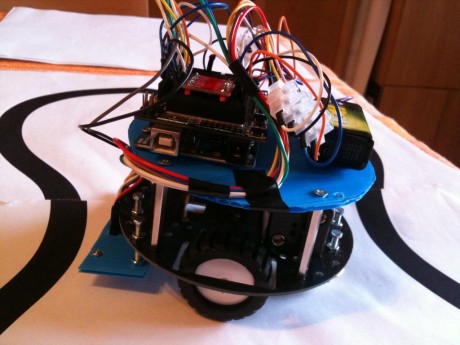

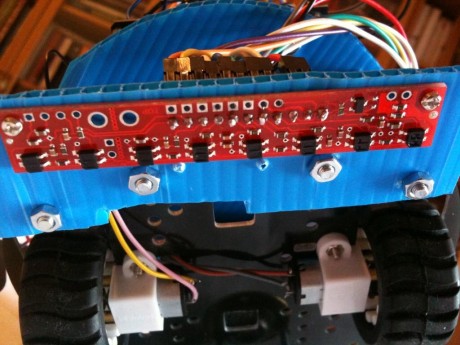

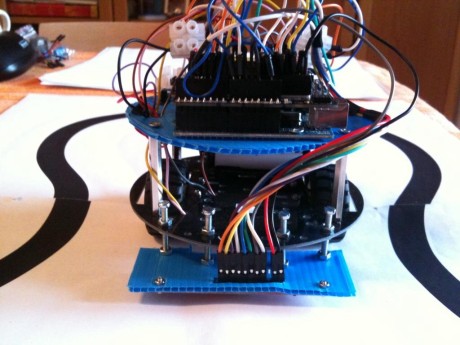

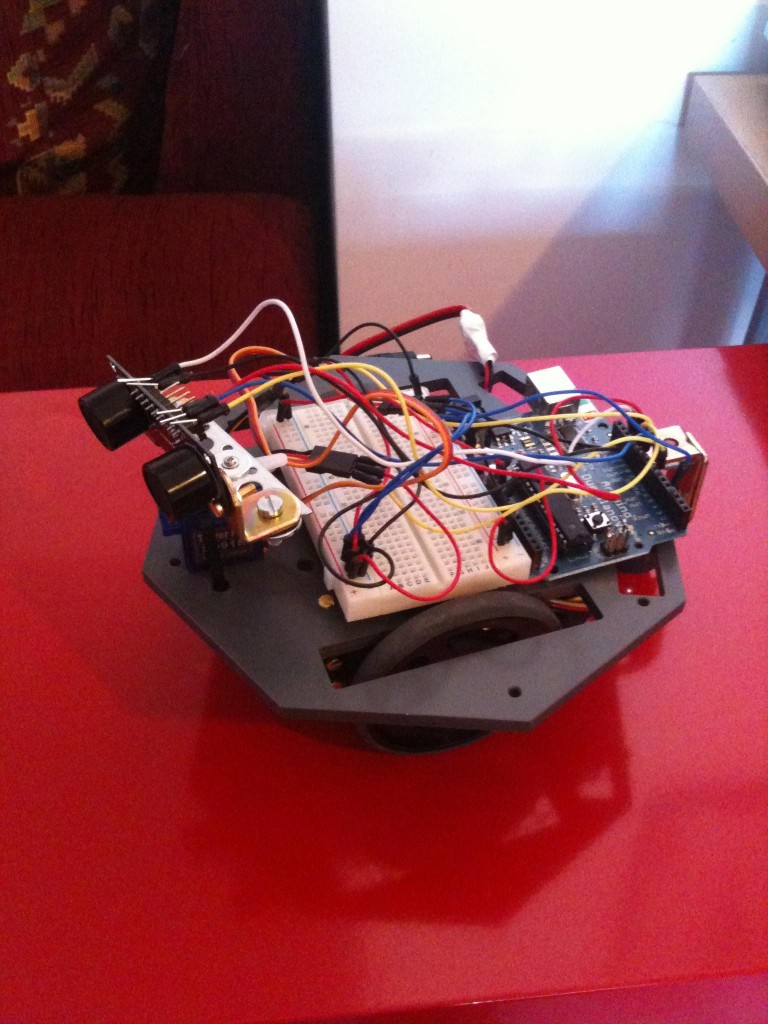

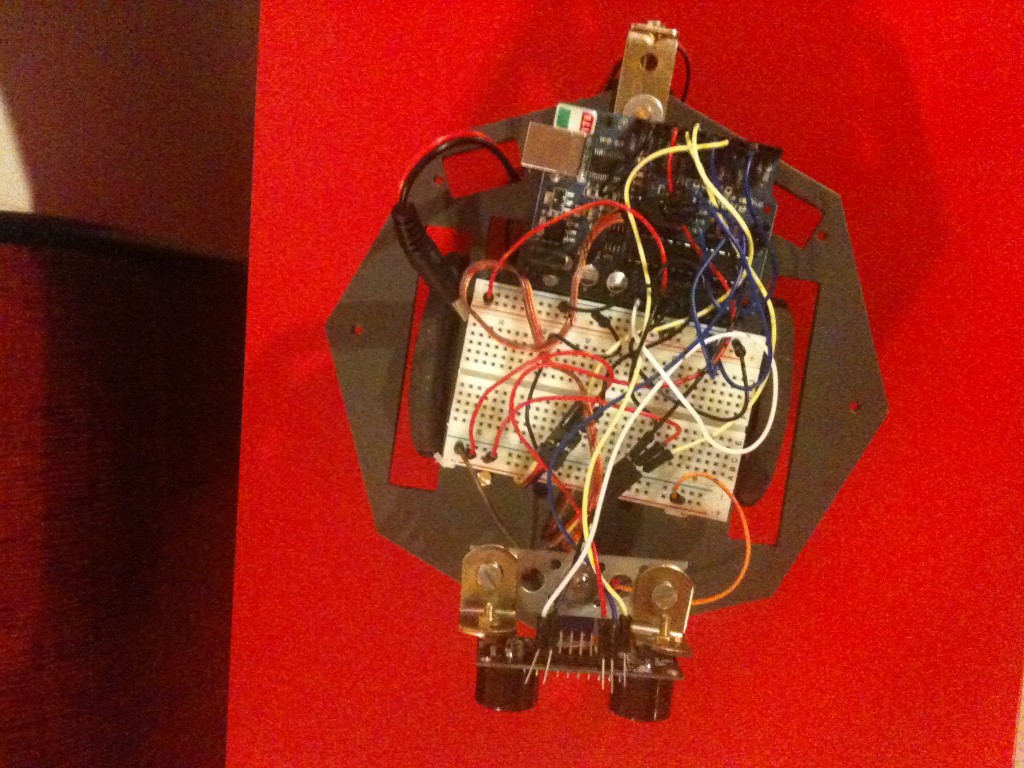

This robot was shown on the Arduino Day, in Rome (Italy), in April 2011 and use a Pololu sensor with 8 IR leds ( link), very cheap (14 euros). It is offered with an Arduino library, made by Pololu. This library resolves all the interfacing problems with Arduino (yeah!).

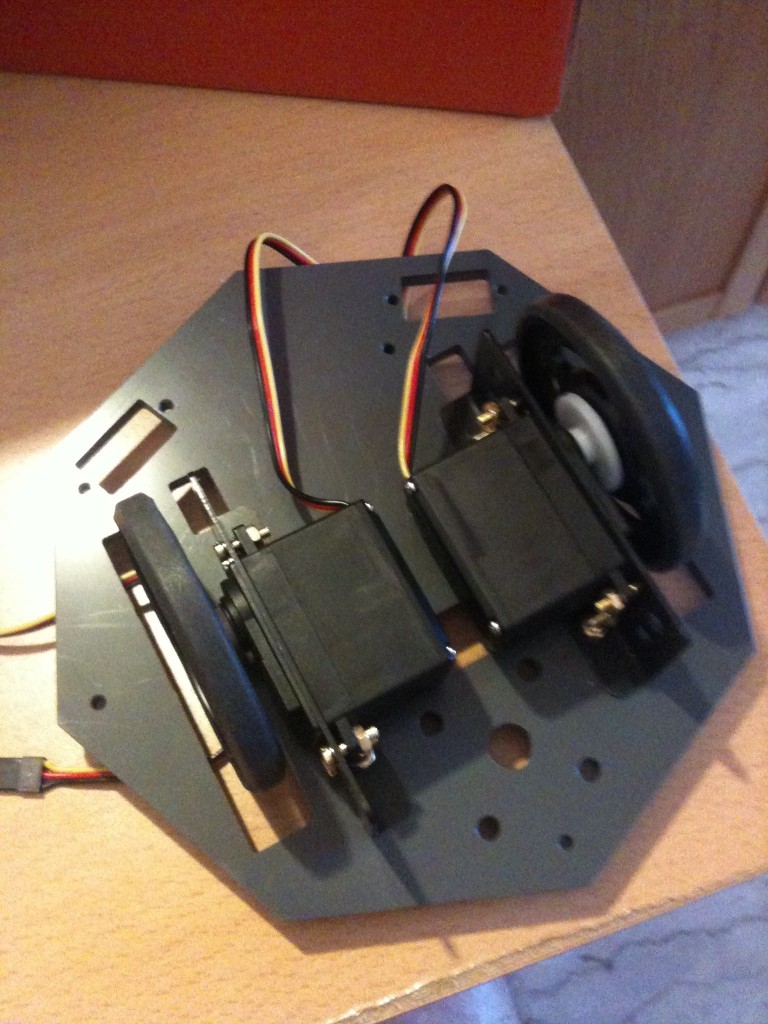

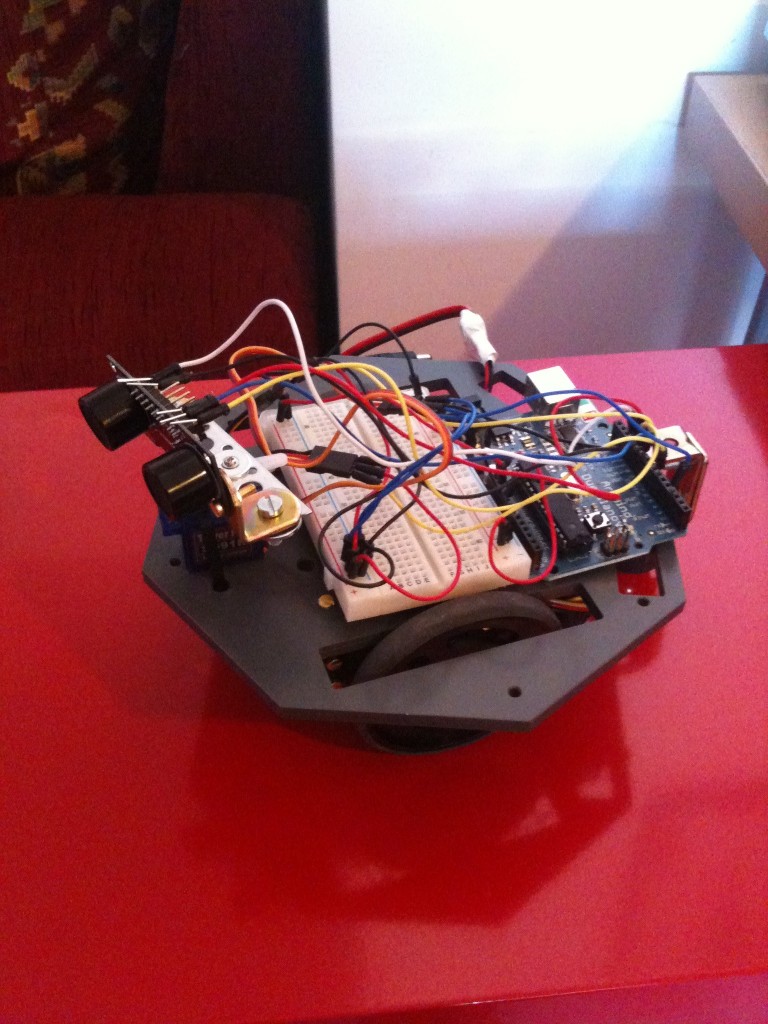

The robot chassis is build using a cheap DFRobot module (link) that for less than 30 euros, offers also 2 gear motors, 2 motor supports and 2 wheels:

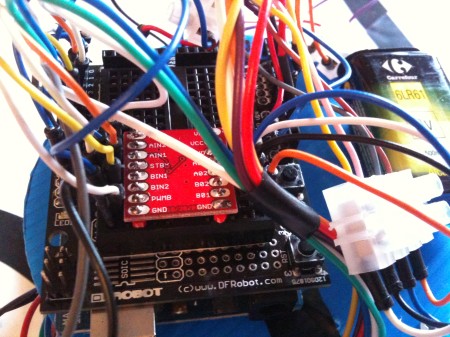

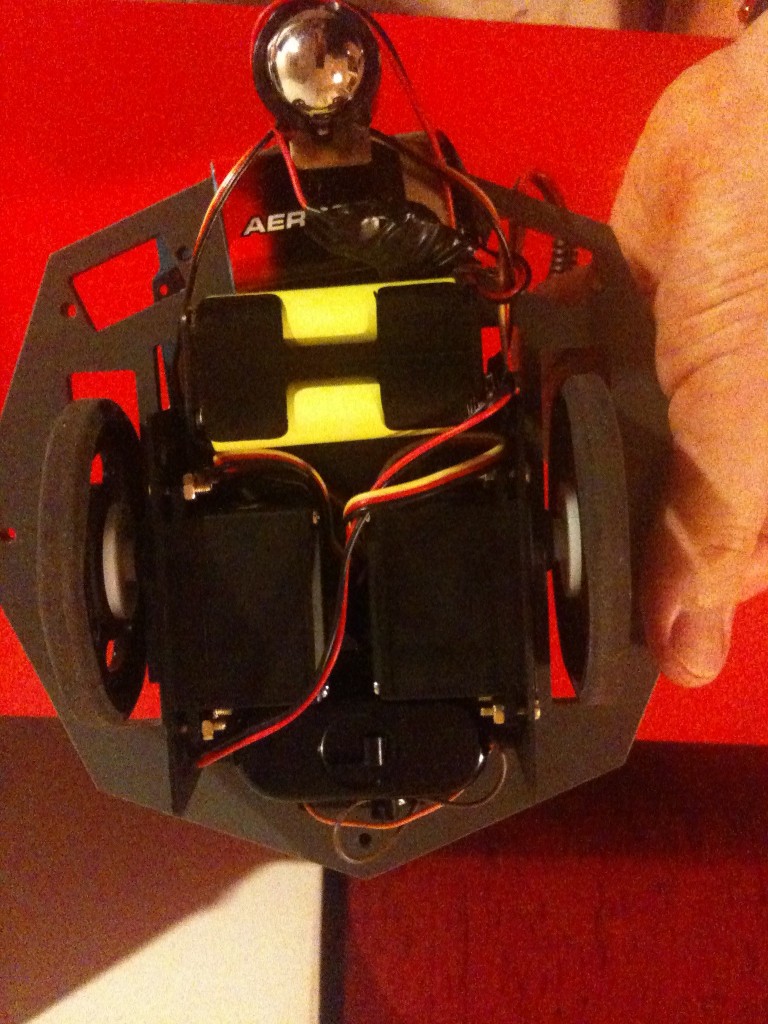

The motor driver is a Sparkfun module (link) , very very cheap (8 euros), that can feed up to 1.2A. It supports 2 gear motors and lets the PWM usage.

The motor driver is a Sparkfun module (link) , very very cheap (8 euros), that can feed up to 1.2A. It supports 2 gear motors and lets the PWM usage.

For my convenience I assembled the motor drivers on a breadboard shield, but it is enough a normal breadboard. Others components (ball caster, sensor support, batteries) are self made or bought in a hardware shop.

For my convenience I assembled the motor drivers on a breadboard shield, but it is enough a normal breadboard. Others components (ball caster, sensor support, batteries) are self made or bought in a hardware shop.

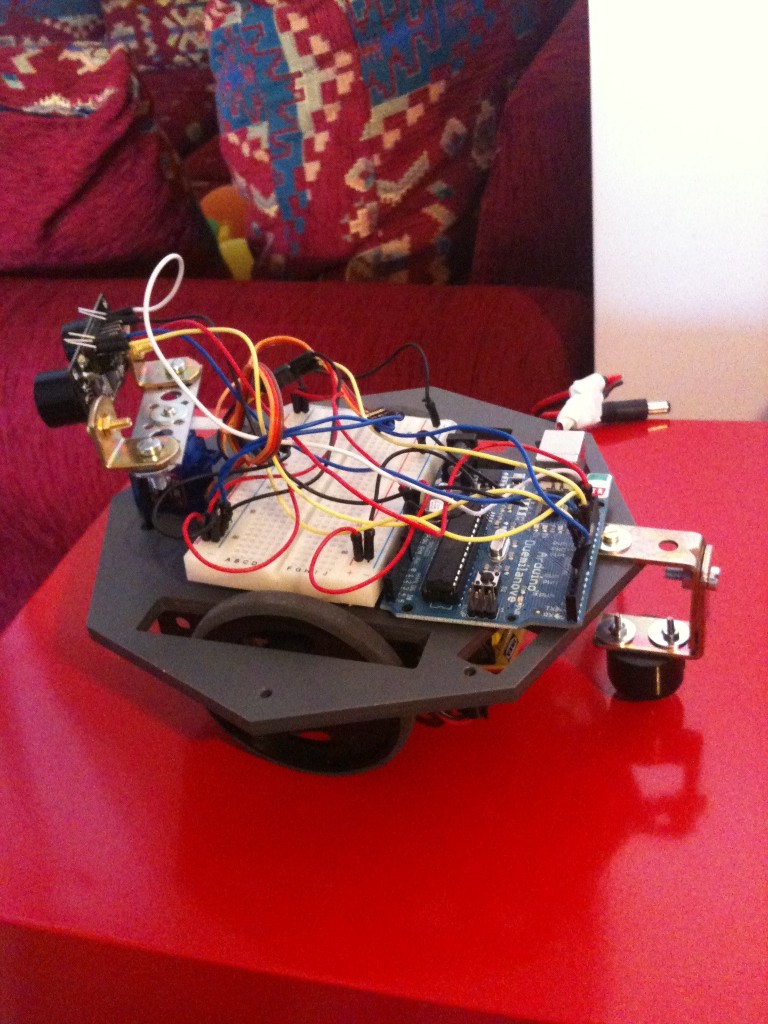

This is Linea:

Here Linea in action:

This is the code used:

#include <PololuQTRSensors.h> // motor driver pin #define out_STBY 6 #define out_B_PWM 9 #define out_A_PWM 3 #define out_A_IN2 4 #define out_A_IN1 5 #define out_B_IN1 7 #define out_B_IN2 8 #define motor_A 0 #define motor_B 1 #define motor_AB 2 #define NUM_SENSORS 8 // number of sensors used - numero di sensori usati #define TIMEOUT 2500 // waits for 2500 us for sensor outputs to go low - aspetta 2500 us prima di mandare low i sensori //define QTR pololu sensor PololuQTRSensorsRC qtrrc((unsigned char[]) {2, 12, 11, 10, 17, 16, 15, 14} , NUM_SENSORS, TIMEOUT, 255); unsigned int sensors[NUM_SENSORS]; void setup() { Serial.begin(115200); // define motor drive output pin - definisci i pin di output del motore pinMode(out_STBY,OUTPUT); pinMode(out_A_PWM,OUTPUT); pinMode(out_A_IN1,OUTPUT); pinMode(out_A_IN2,OUTPUT); pinMode(out_B_PWM,OUTPUT); pinMode(out_B_IN1,OUTPUT); pinMode(out_B_IN2,OUTPUT); motor_standby(false);// motor stand-by off and stop - togli i motori dallo stand-by e fermali stopMotors(); delay(2000); SensorCalibration(); // sensor calibration - calibra i sensori delay(2000); } void loop() { follow_segment(); // follow the black line - segui la linea nera } // PID parameters int Kp=120; int Ki=100; int Kd=100; // follow the black line - segui la linea nera void follow_segment() { int last_proportional = 0; long integral=0; int primo=0; int posizione = qtrrc.readLine(sensors); // read the IR sensors - leggi i sensori IR long int proportional = posizione; int P = proportional * Kp/1000; // Proportional parameter long int derivative = proportional - last_proportional; //Derivative parameter if (primo==0) // firt cycle set derivative to zero - al primo giro imposta il derivativo a zero { primo=1; derivative=0; } int D=derivative*Kd/1000; integral += proportional; int I=integral*Ki/1000; //integral parameter // Remember the last position - ricorda l'ultima posizione last_proportional = proportional; int PID =P + I + D; //calculate the PID // print some values on the serial port - scrivi qualche valore sulla seriale unsigned char zz; for (zz = 0; zz < NUM_SENSORS; zz++) { Serial.print(sensors[zz]); Serial.print(' '); } Serial.print(" position: "); Serial.print(posizione); Serial.print(" P:"); Serial.print(P); Serial.print(" I:"); Serial.print(I); Serial.print(" D:"); Serial.print(D); Serial.print(" PID:"); Serial.print(PID); // set the values for the motors based on the PID gain - setta i valori del motore basati sul PID const int maximum = 40; // the maximum speed if (PID > 0){ if (PID > maximum) PID=maximum; motor_speed2(motor_B,maximum); motor_speed2(motor_A,maximum-PID); Serial.print(" Motore_B:"); Serial.print(maximum); Serial.print(" Motore_A:"); Serial.print(maximum-PID); } else { if (PID < -maximum) PID=-maximum; motor_speed2(motor_B,maximum+PID); motor_speed2(motor_A,maximum); Serial.print(" Motore_B:"); Serial.print(maximum+PID); Serial.print(" Motore_A:"); Serial.print(maximum); } Serial.println(""); } // ------------------ stop the robot - ferma il robottino ----------------------- void stopMotors(){ motor_brake(motor_A); motor_brake(motor_B); } // ------------------ Motor driver mgmt routines - routine per gestire i motori ----------------------- void motor_speed2(boolean motor, char speed) { //speed from 0 to 100 if (motor == motor_A) speed = -speed; byte PWMvalue=0; PWMvalue = map(abs(speed),0,100,50,255); //anything below 50 is very weak if (speed > 0) motor_speed(motor,0,PWMvalue); else if (speed < 0) motor_speed(motor,1,PWMvalue); else { motor_coast(motor); } } void motor_speed(boolean motor, boolean direction, byte speed) { //speed from 0 to 255 if (motor == motor_A) { if (direction == 0) { digitalWrite(out_A_IN1,HIGH); digitalWrite(out_A_IN2,LOW); } else { digitalWrite(out_A_IN1,LOW); digitalWrite(out_A_IN2,HIGH); } analogWrite(out_A_PWM,speed); } else { if (direction == 0) { digitalWrite(out_B_IN1,HIGH); digitalWrite(out_B_IN2,LOW); } else { digitalWrite(out_B_IN1,LOW); digitalWrite(out_B_IN2,HIGH); } analogWrite(out_B_PWM,speed); } } // stand-by motor void motor_standby(boolean state) { //low power mode if (state == true) digitalWrite(out_STBY,LOW); else digitalWrite(out_STBY,HIGH); } // stop the motors void motor_brake(boolean motor) { if (motor == motor_A) { digitalWrite(out_A_IN1,HIGH); digitalWrite(out_A_IN2,HIGH); } else { digitalWrite(out_B_IN1,HIGH); digitalWrite(out_B_IN2,HIGH); } } // motors coast - fai girare i motori in folle void motor_coast(boolean motor) { if (motor == motor_A) { digitalWrite(out_A_IN1,LOW); digitalWrite(out_A_IN2,LOW); digitalWrite(out_A_PWM,HIGH); } else { digitalWrite(out_B_IN1,LOW); digitalWrite(out_B_IN2,LOW); digitalWrite(out_B_PWM,HIGH); } } // IR sensor calibration void SensorCalibration() { int counter, i; for (counter=0; counter<40; counter++) { if (counter < 10 || counter >= 30) { motor_speed2(motor_A,10); motor_speed2(motor_B,-10); } else { motor_speed2(motor_A,-10); motor_speed2(motor_B,10); } qtrrc.calibrate(); // Since our counter runs to 80, the total delay will be // 80*20 = 1600 ms. delay(20); } // print the calibration minimum values measured when emitters were on for (i = 0; i < NUM_SENSORS; i++) { Serial.print(qtrrc.calibratedMinimumOn[i]); Serial.print(' '); } Serial.println(); // print the calibration maximum values measured when emitters were on for (i = 0; i < NUM_SENSORS; i++) { Serial.print(qtrrc.calibratedMaximumOn[i]); Serial.print(' '); } Serial.println(); Serial.println(); stopMotors(); delay(2000); }